5 Common Mistakes to Avoid When Installing and Operating Liquid Jet Eductors

When it comes to efficient fluid handling and mixing, liquid jet eductors are a trusted solution for various industries. At EST Venturi Systems here in The Woodlands, our skilled venturi systems pros understand the critical role these devices play in optimizing processes. However, achieving peak performance from liquid jet eductors requires proper installation and operation. Here are five common mistakes to avoid:

1. Incorrect Sizing of the Eductor

One of the most frequent mistakes is selecting an eductor that is not properly sized for the application. The size of the eductor must align with the flow rate, suction lift, and discharge requirements of your system. An undersized eductor will struggle to meet performance demands, while an oversized one can lead to inefficiencies and increased operational costs. To avoid this mistake, consult with experts like EST Venturi Systems to ensure accurate sizing based on your specific needs.

2. Improper Installation Orientation

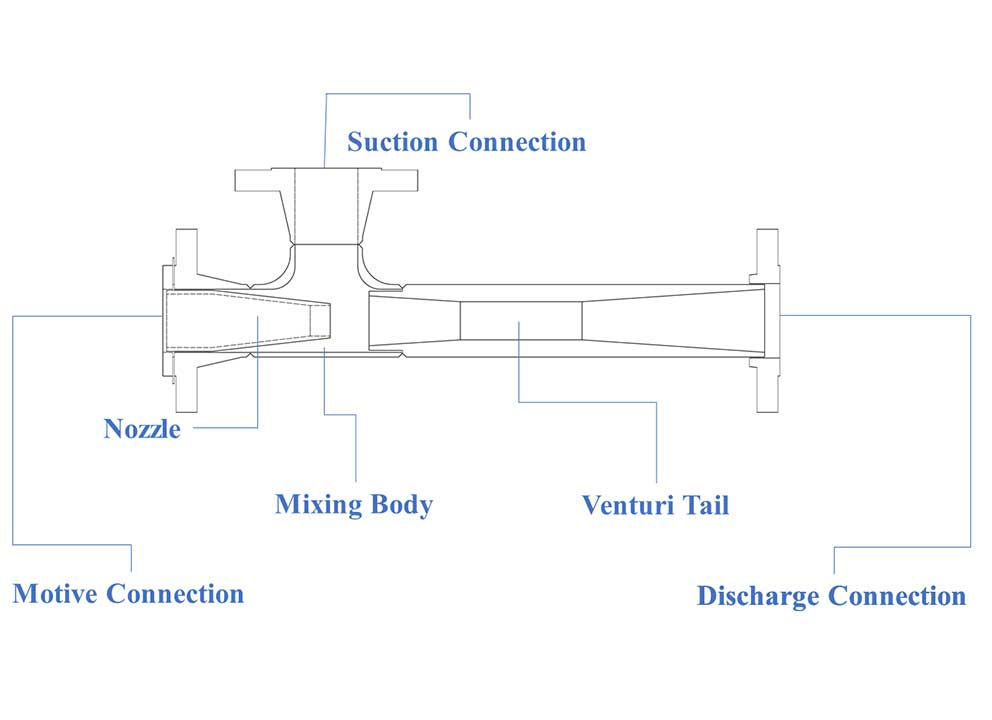

The orientation of the liquid jet eductor is critical to its performance. Incorrect positioning, such as improper alignment with the suction and discharge lines, can cause turbulence and reduce efficiency. Ensure the eductor is installed in accordance with the manufacturer’s guidelines, and verify that all connections are secure and properly aligned. Using professional installation services can help avoid costly errors.

3. Ignoring System Pressure Requirements

Liquid jet eductors rely on the pressure of the motive fluid to create a vacuum and achieve effective operation. Insufficient motive pressure can lead to inadequate suction and mixing, while excessive pressure can damage the eductor or other components in the system. Be sure to monitor and regulate system pressures to stay within the recommended range. EST Venturi Systems provides detailed specifications to help you maintain the ideal operating conditions.

4. Overlooking Maintenance and Inspections

Although liquid jet eductors are known for their durability and low maintenance requirements, they still need regular inspections to ensure optimal performance. Common issues such as clogging, wear and tear, or scaling can degrade efficiency over time. Schedule routine checks to clean and inspect your eductor, especially in systems that handle abrasive or corrosive materials. Implementing a preventative maintenance plan can extend the lifespan of your equipment and prevent unexpected downtime.

5. Failing to Account for Fluid Properties

Not all fluids behave the same, and failing to account for their unique properties can hinder eductor performance. Variables such as viscosity, temperature, and chemical composition can affect suction and mixing capabilities. For example, handling highly viscous or abrasive fluids requires specialized eductors designed to handle such challenges. Work with EST Venturi Systems to select or customize an eductor that matches the specific properties of your process fluids.