How Liquid Jet Eductors Improve Fluid Handling Efficiency in Industrial Applications

Liquid jet eductors play a pivotal role in improving the efficiency of fluid handling systems across various industries. These devices operate on the Venturi principle, which allows them to effectively mix, transport, or pump liquids without the need for moving parts. Their simplicity in design and ability to handle different types of fluids make them a valuable tool in industries like chemical processing, wastewater treatment, and food manufacturing.

Understanding the Venturi Principle

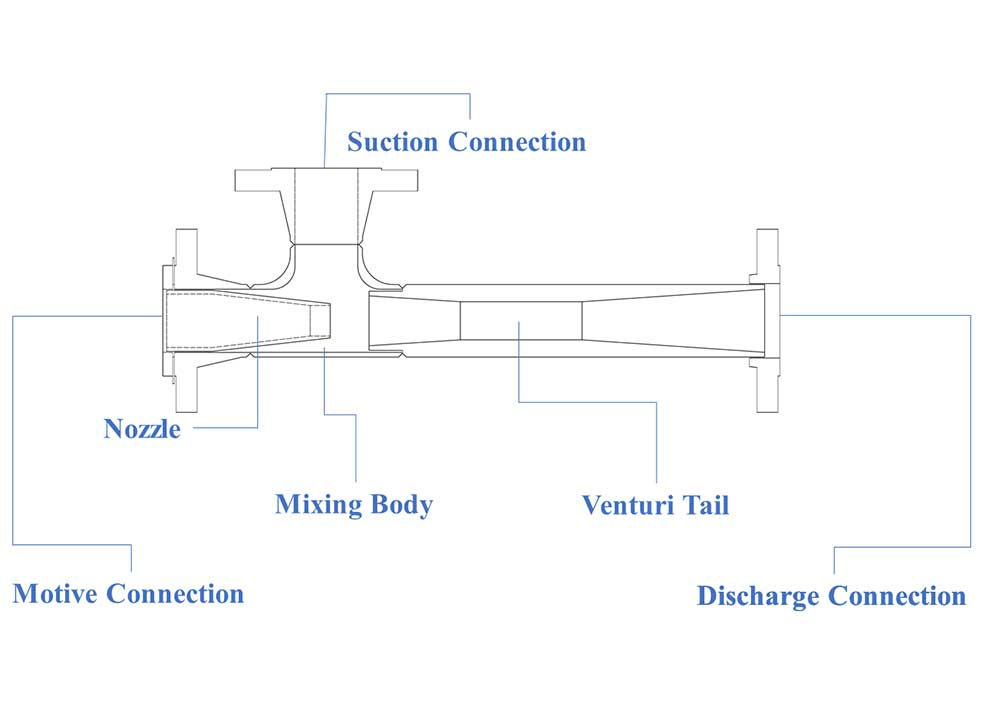

The operation of liquid jet eductors is based on the Venturi effect, a fluid dynamic principle. In simple terms, the eductor uses the pressure energy from a high-velocity fluid stream (motive fluid) to create a vacuum that draws in a secondary fluid (suction fluid). The two fluids mix and are discharged together. This process requires no mechanical pumps or complex parts, which enhances reliability and reduces the risk of failure.

Applications in Key Industries

- Chemical Processing

In the chemical processing industry, liquid jet eductors are used for mixing and transferring chemicals, both hazardous and non-hazardous. Their ability to handle corrosive fluids without the risk of wear and tear from moving parts makes them ideal for such applications. By eliminating the need for conventional pumps, eductors reduce maintenance and improve safety in handling aggressive chemicals. - Wastewater Treatment

Liquid jet eductors are also widely used in wastewater treatment plants to aerate, mix, or move fluids within treatment systems. Their ability to create a strong suction and mix fluids efficiently helps in breaking down solids, promoting biological treatment, and reducing the need for complex mechanical systems. Eductors help streamline operations, ensuring cost-effective and energy-efficient wastewater management. - Food Manufacturing

In the food manufacturing industry, liquid jet eductors are used for blending ingredients, transferring liquids, and maintaining hygiene standards due to their simple design. They can handle a wide range of viscosities, from thin liquids like water to more viscous substances like syrups, without contaminating the product. Their ability to reduce downtime and require minimal maintenance makes them indispensable in this sector.

Efficiency, Cost-Effectiveness, and Low Maintenance

One of the primary reasons liquid jet eductors are favored in industrial applications is their efficiency. Without moving parts, they are less prone to wear and tear, significantly reducing maintenance costs. Additionally, they operate using existing fluid pressure, which eliminates the need for additional power sources like mechanical pumps. This energy-efficient design leads to lower operating costs and enhances overall system efficiency.

Liquid jet eductors also contribute to system simplicity. Their ease of installation and versatility allow them to be integrated into existing systems with minimal modification. By reducing the need for complex machinery and continuous monitoring, they ensure a smooth and efficient fluid handling process.

In conclusion, liquid jet eductors provide a cost-effective, energy-efficient, and low-maintenance solution for various industries. Their ability to improve fluid handling systems while minimizing operational costs makes them an essential component in modern industrial applications. Contact for liquid jet educators in The Woodlands.