Understanding Jet Exhausters: What They Do and Why They Matter

Jet exhausters play a crucial role in various industrial and commercial applications, but understanding their function and significance can be a bit challenging without a technical background. This blog aims to demystify jet exhausters, explaining their purpose, how they work, and the benefits they offer.

What Are Jet Exhausters?

Jet exhausters, also known as ejectors or eductors, are devices that utilize the Venturi effect to create a vacuum or move fluids. They are used in a wide range of applications, from chemical processing and power plants to HVAC systems and environmental engineering. The primary purpose of a jet exhauster is to transport gasses, liquids, or solids using a high-velocity jet of steam, air, or other gasses.

How Do Jet Exhausters Work?

The operation of a jet exhauster is based on the principles of fluid dynamics. Here's a simplified breakdown of the process:

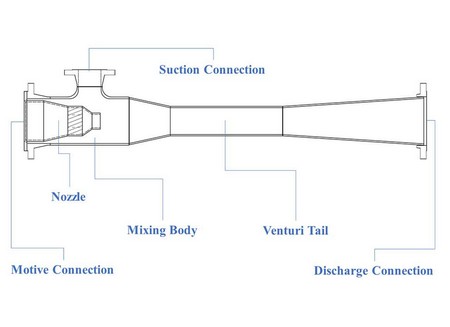

- High-Pressure Fluid Injection: A high-pressure fluid (often steam, air, or water) is injected into the jet exhauster through a nozzle. This fluid is referred to as the motive fluid.

- Venturi Effect: As the motive fluid passes through the nozzle, it accelerates and creates a low-pressure zone in the exhauster. This phenomenon is known as the Venturi effect.

- Suction and Mixing: The low-pressure zone draws in the secondary fluid (the fluid to be transported). The motive fluid and the secondary fluid mix in the mixing chamber.

- Discharge: The mixed fluid is then discharged from the exhauster at a higher pressure and velocity than the secondary fluid initially had.

Applications of Jet Exhausters

Jet exhausters are versatile and can be found in various industries:

- Chemical and Petrochemical Industries: Used for evacuating gasses, vapor recovery, and mixing fluids.

- Power Plants: Help in condenser exhausting, flue gas scrubbing, and fly ash handling.

- HVAC Systems: Aid in creating vacuums for air conditioning and refrigeration systems.

- Environmental Engineering: Assist in groundwater remediation and soil vapor extraction.

Advantages of Using Jet Exhausters

Jet exhausters offer several benefits that make them an attractive choice for many applications:

- 1. No Moving Parts: One of the most significant advantages is that jet exhausters have no moving parts. This feature translates to lower maintenance requirements and a longer operational lifespan.

- 2. Reliability and Durability: Due to their simple design, jet exhausters are highly reliable and durable, capable of operating in harsh environments and under varying conditions.

- 3. Cost-Effective: They are generally more cost-effective than mechanical pumps or compressors, both in terms of initial investment and long-term operation.

- 4. Flexibility: Jet exhausters can handle a wide range of fluids, including gases, liquids, and slurries. They are also adaptable to different pressures and flow rates, making them suitable for diverse applications.

- 5. Energy Efficiency: When properly designed and operated, jet exhausters can be energy-efficient, especially in applications where the motive fluid is readily available, such as steam in power plants.

Jet exhausters are invaluable tools in many industrial processes, providing efficient and reliable fluid transport solutions. Understanding how they work and their applications can help in making informed decisions about their use in various projects. Their simplicity, reliability, and cost-effectiveness make them a preferred choice in numerous industries, proving that sometimes, the simplest solutions are the most effective.

Call for jet exhausters in The Woodlands. We're the top choice in the area for liquid jet eductors and related services.